-40%

Rotary Rotavap Rotavapor Evaporator Essential Oil Steam Distillation Equipment

$ 489.45

- Description

- Size Guide

Description

Rotary Rotavap Rotavapor Evaporator Essential Oil Steam Distillation EquipmentA rotary evaporator is a device used in chemical laboratories for the efficient and gentle removal of solvents from samples by evaporation. When referenced in the chemistry research literature, description of the use of this technique and equipment may include the phrase "rotary evaporator", though use is often rather signaled by other language (e.g. "the sample was evaporated under reduced pressure").Rotary evaporators are also used in molecular cooking for the preparation of distillates and extracts.

Specification

:

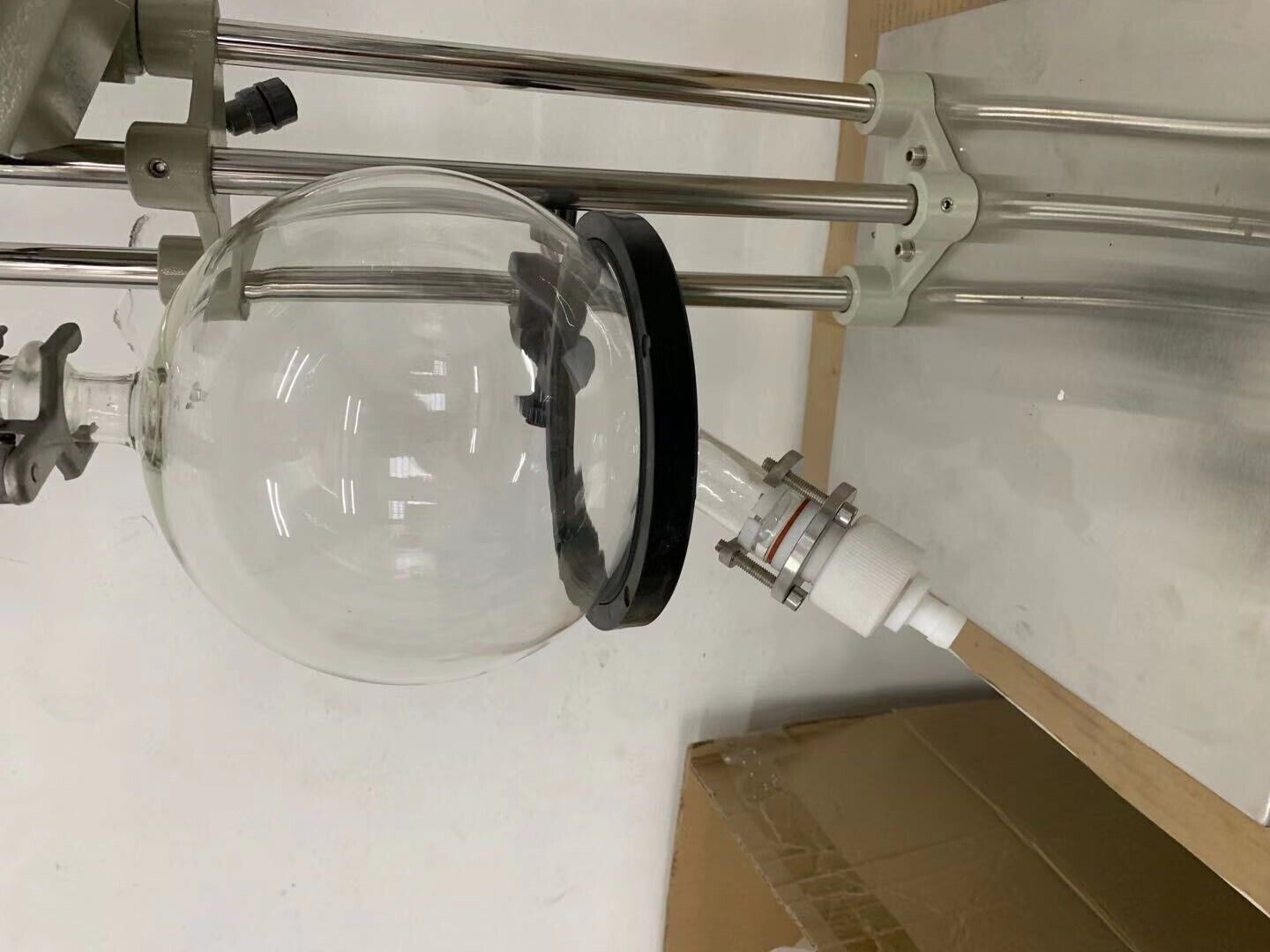

1. Capacity of evaporating flask: 5L

2. Capacity of collecting flask: 3L

3. Vacuum: -0.098Mpa

4.Rotating speed: 0 - 90 R/min

5. Evaporating speed: ≥1.5L/H20

6.

Temperature range:Room temperature-99℃

7. Motor power: 60W

8. Water bathing power: 1.5KW

9. Voltage: 110V

Features

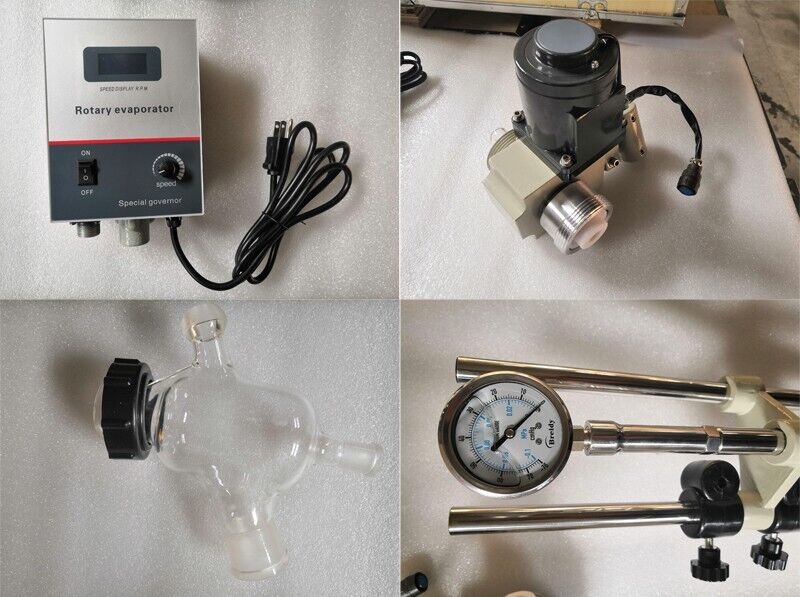

Rotator consist of a group of reliable micro motor and integrated circuit control device. Under the effect of the electronic speed regulation, it can be rotated stably within the range of 10-120rpm, reaching the international advanced level

1. Special fluoro rubber sealing, high corrosion resistance.

2. High evaporating efficiency & high recovery.

3. Modular design, easy to connect to other appliance.

4. Easy to install and disassemble, easy to operate & maintain.

5. The main body extensively adopts stainless steel and aluminum alloy, firm and beautiful

6. RE-501 rotary evaporator's heating bath is lifed manually, lifting distance is 120mm

7. Two kinds of condenser structures for choosing, one adopts double line convection principle, used for inorganic solvent evaporation. The other is a single line container with a interlayer cooled by water and dry ice, used or evaporating the organic solvent. Using vertical condenser to save space.

8. The rotating shaft using high borosilicate glass, the joints using fluorine rubber framework oil seal to seal, high tightness and better effect

Foam removal method:

1. Condenser bottle mouth downward to let the foam out by itself.

2. Do not shake the condenser when there is a small amount of foam left in the condenser. Shaking is easy to damage the glass tube in the condenser.

An acidic liquid can be poured into the condenser to dissolve the foam.

On Dec 26, 2022 at 23:18:23 PST, seller added the following information: